HIGHLAND CRAFTSMEN FOUNDEDBy Marty And Chris McCurry1990

The Bark House was co-founded by Marty and Chris McCurry in 1990. The aim was to demonstrate what a business system could be when following the wisdom of the forest and partnering with the land. Ours would be a regenerative manufacturing process, in contrast to contemporary extractive business practices.

Co-founder Marty McCurry designed and created the first manufactured bark shingles and bark wall panels as well as all of the procurement, manufacturing, and installation methods. Most noteworthy is his development of the only grading and drying standards for bark in architectural projects. The Bark House Bark Grading and Manufacturing Standards ensure that Bark House products are pure and suitable for their intended use.

Chris enlivened the field of regenerative practice and whole systems throughout the Bark House manufacturing process. Employees, vendors, clients, and the community were engaged as partners to the land. She focused on how to support the connection of the Appalachian people to their beloved forests.

FIRST APPLICATIONFamily Home In Highlands, North Carolina1993

The first application of poplar bark shingles on new construction was in Highlands, NC. Marty used this as an opportunity to test his theories on installation methods and material response.

BARK SHINGLE PRODUCTION INCREASES 1995

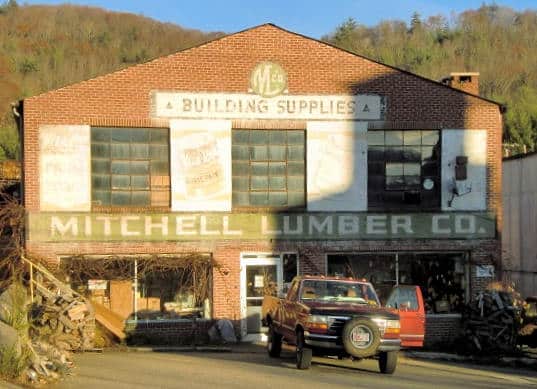

An agreement was formalized between Marty McCurry and Bud Phillips, the owner of Mitchell Lumber Company. McCurry would lease space and equipment; reclaim bark from the felled timber; and implement his proprietary grading and manufacturing standards at the sawmill where lumber production had decreased from years past.

FIRST DEVELOPMENTLinville Resort, Eseeola Lodge1996

Linville NC is the birthplace of the first squared edge bark shingle that was made from Chestnut bark in the late 1800’s. Six structures were shingled at the specification of a young Henry Bacon, who would claim enormous fame in his later career as an architect. The Eseeola Lodge was at the center of what grew to be a unique resort community. It was a tremendous honor for our first application of the Bark House Shingle in a land development to be in Linville Resort.

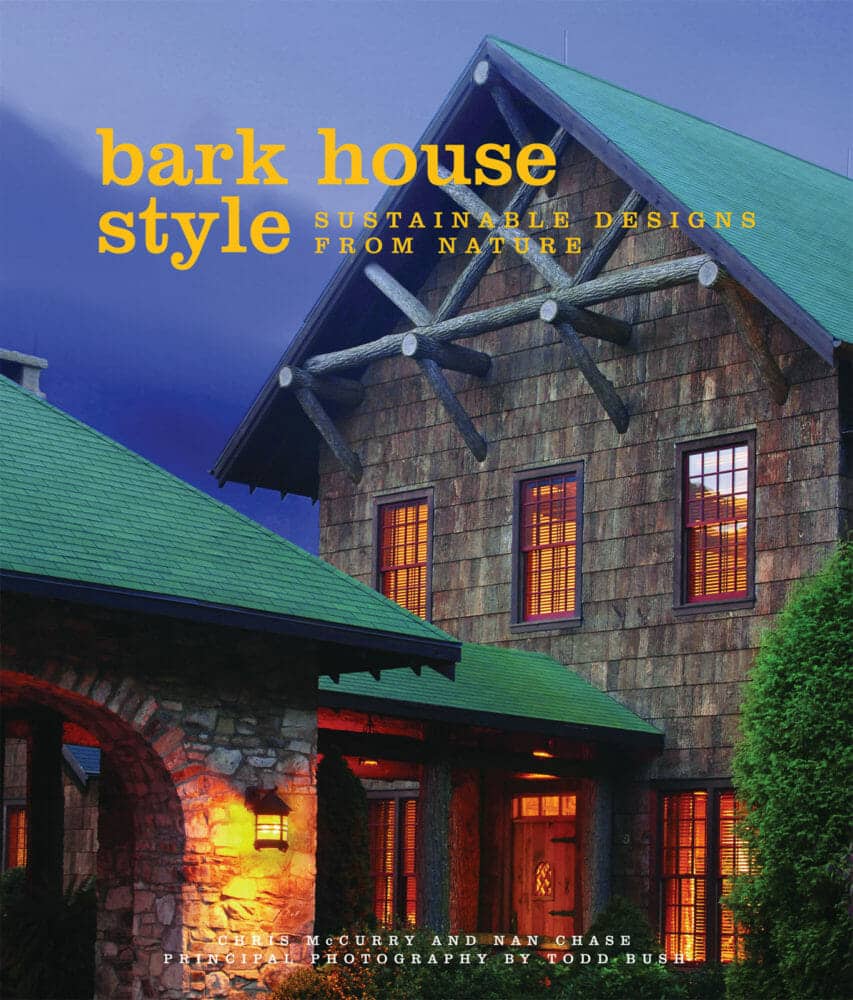

Read more about the history in Bark House Style, Sustainable Designs From Nature.

MEETING A MISSION GOALCreating Regional Economic Growth1998

We met our Mission Goal by expanding a positive economic impact in our community. We trained qualified, professional loggers in the proper procurement and handling of poplar bark for shingles.

Company co-founder Marty McCurry trained 50 loggers who were hand-selected for their care of the land and engagement in best management practices. By selling us the bark, they could earn enough money in three months to self-finance the purchase of their equipment. Loans are largely unavailable for small logging operations.

With a sense of partnership with the land, they were improving 10-acre stands of trees for small landowners. The work of peeling back the bark is hard but economically worthwhile – and environmentally sound. Today, The Bark House has trained over a thousand loggers and works with over 250 independently operated businesses each year from 13 states and 45 counties in Appalachia, increasing their income threefold for each log by selling us the waste bark from poplar trees.

New Bark House® Product DebutMassive Poplar Bark Panels Introduced to the Market1999

Co-founder Marty McCurry designed and created the first manufactured monolithic poplar panels.

Only one in one thousand poplar trees will yield a sheet of bark this large without cracking, making them incredibly rare. They are carefully carried by hand from the forest at double the weight of the finished product. Only when they meet the official Bark House Bark Grading Standard, the poplar panels are meticulously kiln-dried with proprietary methods and manufactured for our clients.

What The Wall Street Journal Got Wrong1999

The first nationally syndicated article ever written on poplar “bark panels” appears in the Wall Street Journal.

The article loosely links poplar bark structures with the historic Adirondacks. Readers erroneously followed suit building Poplar Bark sided “Adirondack Style” houses in the mountains of NC and surrounding states as if there was no relevant regional architecture to glean inspiration from.

Although Hugh MacRae was not as wealthy as Rockefeller, and his development in Linville, NC was not as famous as the Great Camps of NY, his work and contribution were significant. In the late 1800’s MacRae needed a fresh aesthetic for his elite development in Linville – one of his many land holdings that included Grandfather Mountain. He recruited the classically trained architect and family friend who had grown up in Wilmington and vacationed with the family in their much beloved NC mountains. Henry Bacon, AIA designed many monuments including the Lincoln Memorial, and was the only Architect in history to receive the Gold Medal from a President of the United States in full ceremony preceded by a grand procession down the length of the reflecting pool in Washington DC. He designed the first squared bark shingle in 1895, a fact not widely published until this company owner’s book was released by Gibbs Smith in 2008. Six structures were erected at Bacon’s specification in Old Linville.

CURRENT MANUFACTURING FACILITY PURCHASEDSpruce Pine, NC2000

The current manufacturing facility was purchased in Spruce Pine, NC. The location is on the Blue Ridge Parkway between Asheville and Boone.

Marty McCurry engineered and built the first dry kilns ever used in the drying of poplar bark. The kiln design and performance earned the Governor’s NC Green Innovation Award.

The details of our buildings and brownfield reclamation can be read here.

Second DevelopmentDiamond Creek2000

In partnership with Wayne Huizenga, John and Sharon McNeely created an exclusive mountain resort in Western North Carolina appropriately named Diamond Creek. Huizenga has been involved in the founding of three Fortune 500 corporations and is responsible for six New York Stock Exchange listed companies. He has also been an owner of three top tier professional sports franchises. Golf professional John McNeely with his wife Sharon envisioned a golf club featuring a Tom Fazio designed championship golf course. This was the first time a newly developed resort created their design aesthetic around our poplar bark shingles.

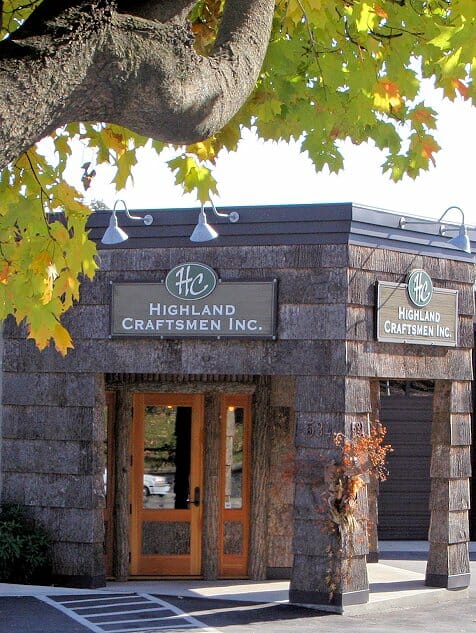

Incorporated as Highland Craftsmen Inc2002

First International SaleOrder Shipped To Norway2005

New Bark House® Product DebutCherry, Pine And Birch Bark Interior Wall Covering Laminate Veneers Introduced To The Market2005

Marty McCurry designed and created the first manufactured bark laminates with pure birch, cherry, and pine bark surfaces for interior wall panels.

Brand Name - Bark House®Adopted and Registered 2006

Bark House® is registered and recognized as “the quality brand”.

C2C Gold CertificationOur Response To Green-Washing2007

“The Cradle to Cradle Certified Product Standard is the world’s most ambitious and actionable standard for designing and making products that enable a healthy, equitable, and sustainable future.”

Bark House was certified at the Gold Level, demonstrating the nature of our sustainability commitment.

B Corp Certified2008

“B Corp Certification is a designation that a business is meeting high standards of verified performance, accountability, and transparency on factors from employee benefits and charitable giving to supply chain practices and input materials.”

Bark House earned the B Corp Certification.

Bark House Style, Sustainable Designs From NaturePublished by Gibbs Smith2008

Authored by Chris McCurry and Nan Chase

Current Logo Adopted2010

At the time of adopting our current logo, Bark House had sold products in 49 states.

The outer and inner circles in the logo represent our continuous commitment to partnering with land at every level of our business process.

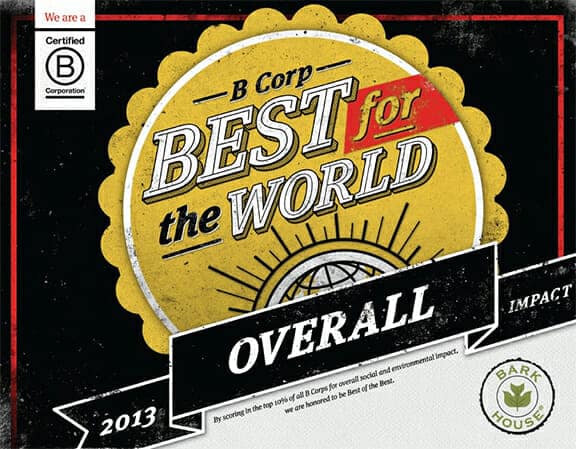

B Corp "Best For The World"Awarded2013

B-Corp measured our strategy to financially and socially empower loggers and residents of the Appalachian region as they work and live in harmony with the forests. We earned the prestigious Best For The World Award.

B Corp "Best For The World"Awarded2014

For the second year in a row, Bark House earned the Best For The World Award.

B Corp "Best For The World"Awarded2015

The achievement of Best for the World companies demonstrates leadership on social and environmental performance — both to the B Corp community and all businesses looking to improve their social and environmental impact. Around our Global Network, B Lab and Sistema B have been celebrating and sharing the significance of this achievement…

Fostering exceptional work environments…Centering positive impact for customers…Creating companies that are integral to their communities…Building a global movement where benefit is essential to business governance.”

2015

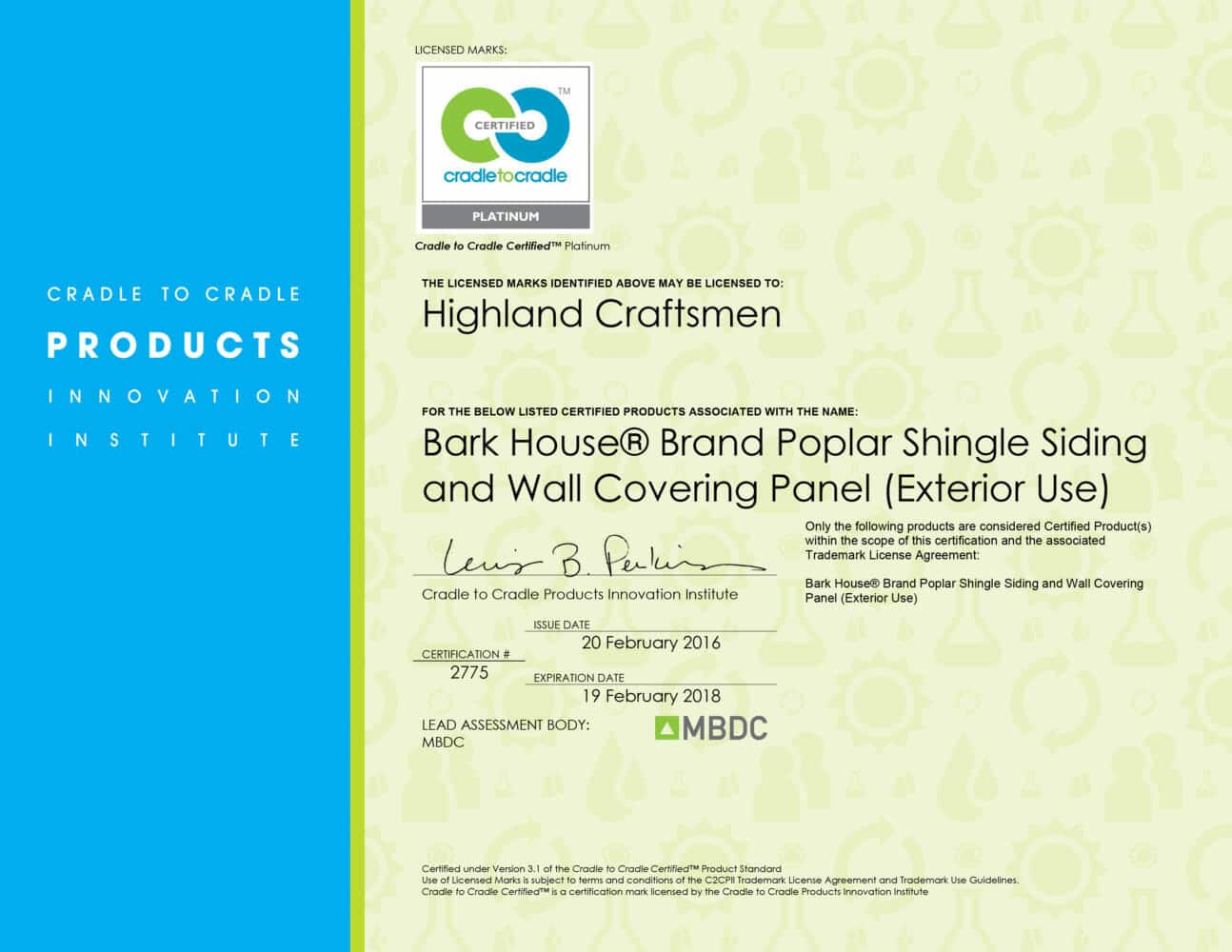

Cradle to Cradle Certified™ PlatinumThe World's First PLATINUM LEVEL Cradle To Cradle Certification2016

Bill McDonough, author of Cradle to Cradle, shared this about Bark House®, “…you are looking at a product that is almost a sacred thing…people are being honored with right-fit jobs, forests are being honored with sustainable forestry, and the buildings that use these materials are being honored with safe, healthy materials.”

For the first time since the creation of the Cradle to Cradle CertifiedTM Products Program, a product—Highland Craftsmen Inc.® Bark House® poplar shingle and wall panel—achieved Platinum-level certification. This highly commendable feat required the product meet Platinum requirements across all five Cradle to Cradle certification categories: material health, material reutilization, renewable energy and carbon management, water stewardship, and social fairness.

Earned Architectural Record Product of the Year2016

Bark House was chosen by a panel of six judges, representing the nation’s leading architectural firms, and selected as one of the best new products of the year from among 425 entries submitted for Architectural Record‘s 11th annual competition. Entries were judged on the criteria of innovation, aesthetics, and purposefulness.

Bark House® Poplar Bark Shingles and Panels were certified by C2C as a Healthy Material. We use no water in direct manufacturing, the product holds more carbon than all of its manufacturing produces, and it biodegrades cleanly at end-of-life to build clean soil.

The pristine nature of the bark connects people to the forest.

Bark House Earns Sanford Institute Regenerative Company AwardFor The Adorning Category2017

Carol Sanford (author of the Regenerative Business series) expressed why people resonate with bark wall finishes when she said “…if I was in a space with Bark House bark wall coverings, I would know that I had found a place where we belong.”

Winner of the Adorning Category from the Carol Sanford Institute, Bark House® Bark Wall Panels honor the essence of the Appalachian forest.

Recognized as a Catalyst Company in the Buckminster Fuller Challenge2018

“Here you will find a comprehensive history of the BFC program and a curated archive of the ‘best of’ entries reviewed by the program from 2007-2017 making visible the vibrancy and dedication of an emerging field of comprehensive, whole-systems designers.”

This award recognizes the commitment of Bark House to elevate the forest system as our teacher of how business can be organized and function as a partner of nature.

John Ruskin Prize Finalist2019

“…the greatest thing a human soul ever does in this world is to see something…To see clearly is poetry, prophecy, and religion – all in one”.

John Ruskin, Modern Painters, vol. 3.

Bark House saw the poetry, prophecy, and religion of bark – as more than an overlooked waste material of the forest industry – so much more than a commodity to be extracted.

Bark House Marks 30 Years in Business2020

Bark House celebrates 30 years in business by actively participating in ForestHer NC. This organization’s mission is to support, educate, and empower a community of women landowners and natural resources professionals to engage in forest conservation and stewardship in North Carolina.