Species

- Black Locust (Robinia pseudoacacia)

Product Dimensions

- Normally triangular in shape, but other configurations will occur.

Standard Lengths

- Rails – 10’ and 11’

- Fence Posts – 7’

Grades

- Government –

- Rail Circumference – 12″-15″

- Post Circumference – 15″-18″

- Average Rail Weight – 50 lbs.

- Average Post Weight – 45 lbs.

- A bundle of 30 will be approx 36″ wide and tall.

- Standard –

- Rail Circumference – 8″-12″

- Post Circumference – 12″-15″

- Average Rail Weight – 40 lbs.

- Average Post Weight – 30 lbs.

Tolerances: Rails are allowed to have a maximum of a 5″ curve or variance from the central axis. Anything over a 5″ curve is not permitted.

Bundle Quantity

- 30 rails per bundle

- 20 posts per bundle

At Bark House®, we only produce authentic wood split rail fencing and posts made from black locust trees. The traditional early method of splitting was accomplished with a mallet and locust wedges. American Chestnut and Black Locust were predominantly used due to their rot resistance and wide availability. By the mid-1900s, the Chestnuts were gone and Black Locust firmly took its place. Steel sledgehammers and wedges replaced their wooden counterparts, but the back-breaking work and sweat were not greatly reduced. We now utilize a massive hydraulic ram to split logs into individual rails but they are still splinter-trimmed by hand with axes. Authenticity is still properly represented as there is no way to tell the difference between our production split rails and ones split the old way. That’s why our largest customers are the federal and state park services and why our fencing will last for generations.

We have researched and compiled numerous construction methods employed throughout different times and regions. These may be viewed from links on this product page.

Figuring the Number of Posts and Rails for Your Project:

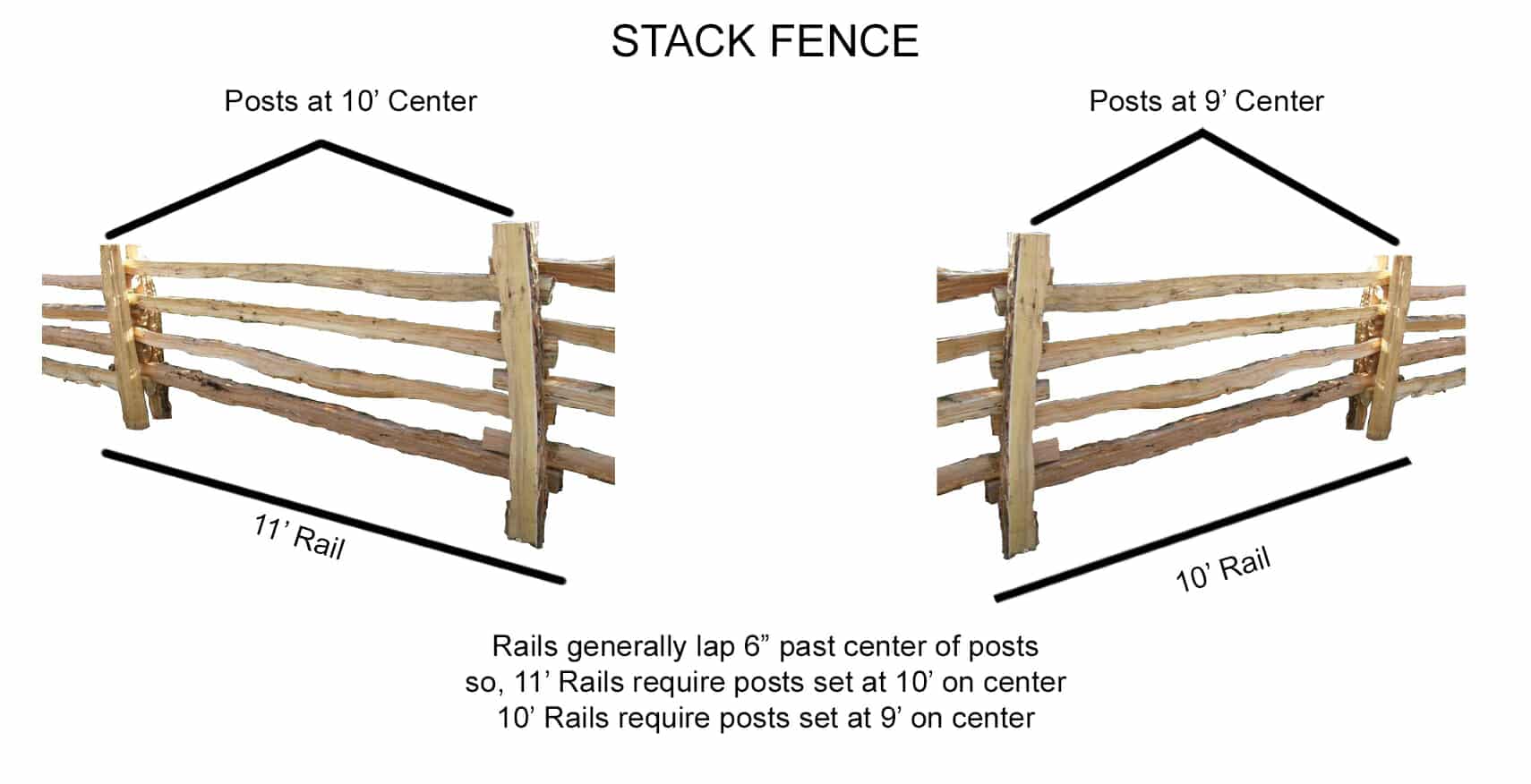

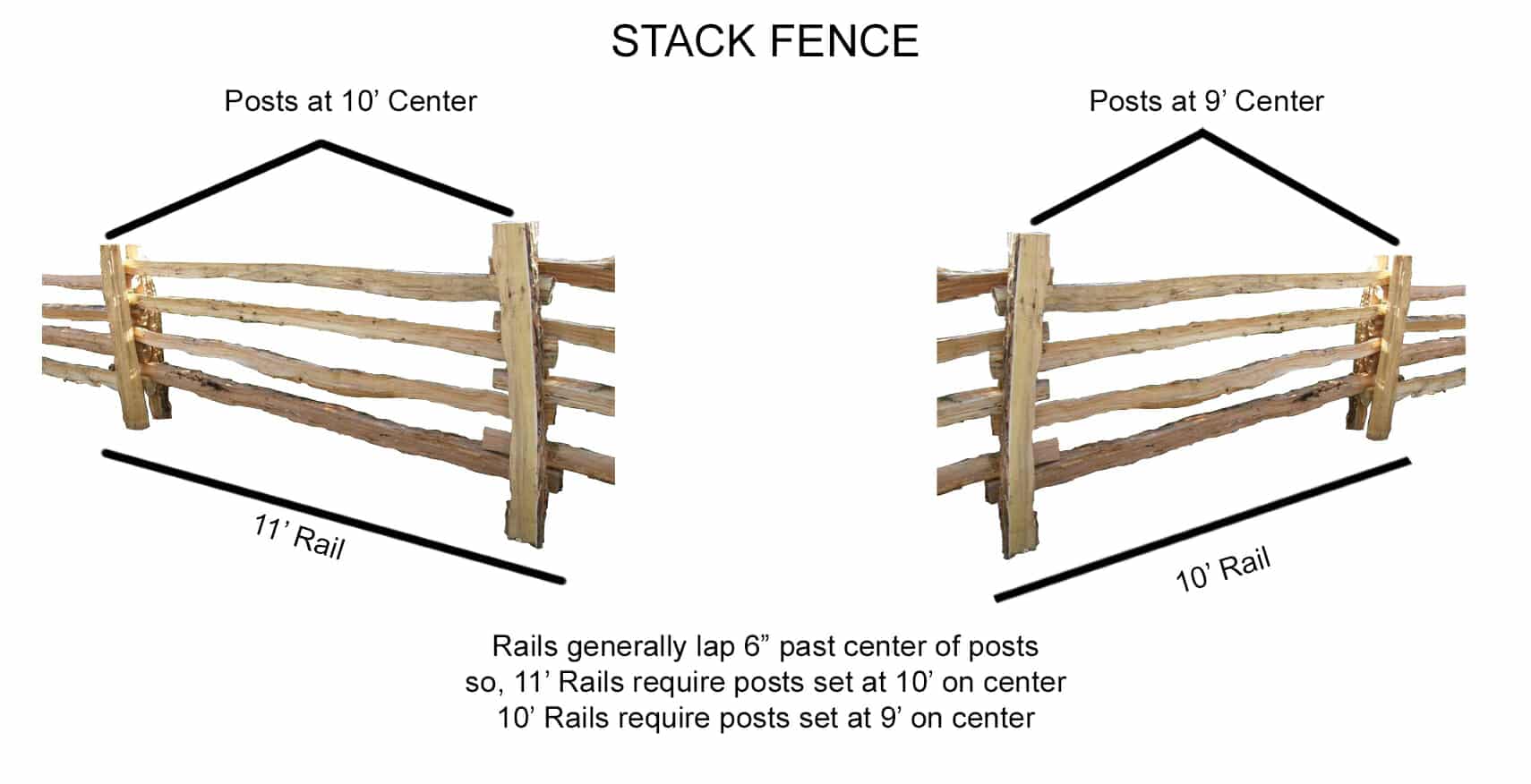

There are two traditional styles of split rail fencing: Stack Fence and Snake Fence. The style that you choose will determine the quantity of rails and posts needed for your project.

- For a straight run: measure the length of the area to be fenced, divide the total linear footage by the rail size you choose (10’ or 11’) to get the number of sections. You will need to figure your rails per section, plus a set of posts at the end, and 2 – 5 rails per section depending on whether you want a 2 rail or 5 rail fence. Allow a minimum of a 1-foot lap at the post intersection from both ends of the rail. 11’ rails require posts set at 10’ on center and 10’rails require posts set at 9’ on center.

- require posts set at 10’ on center and 10’rails require posts set at 9’ on center.

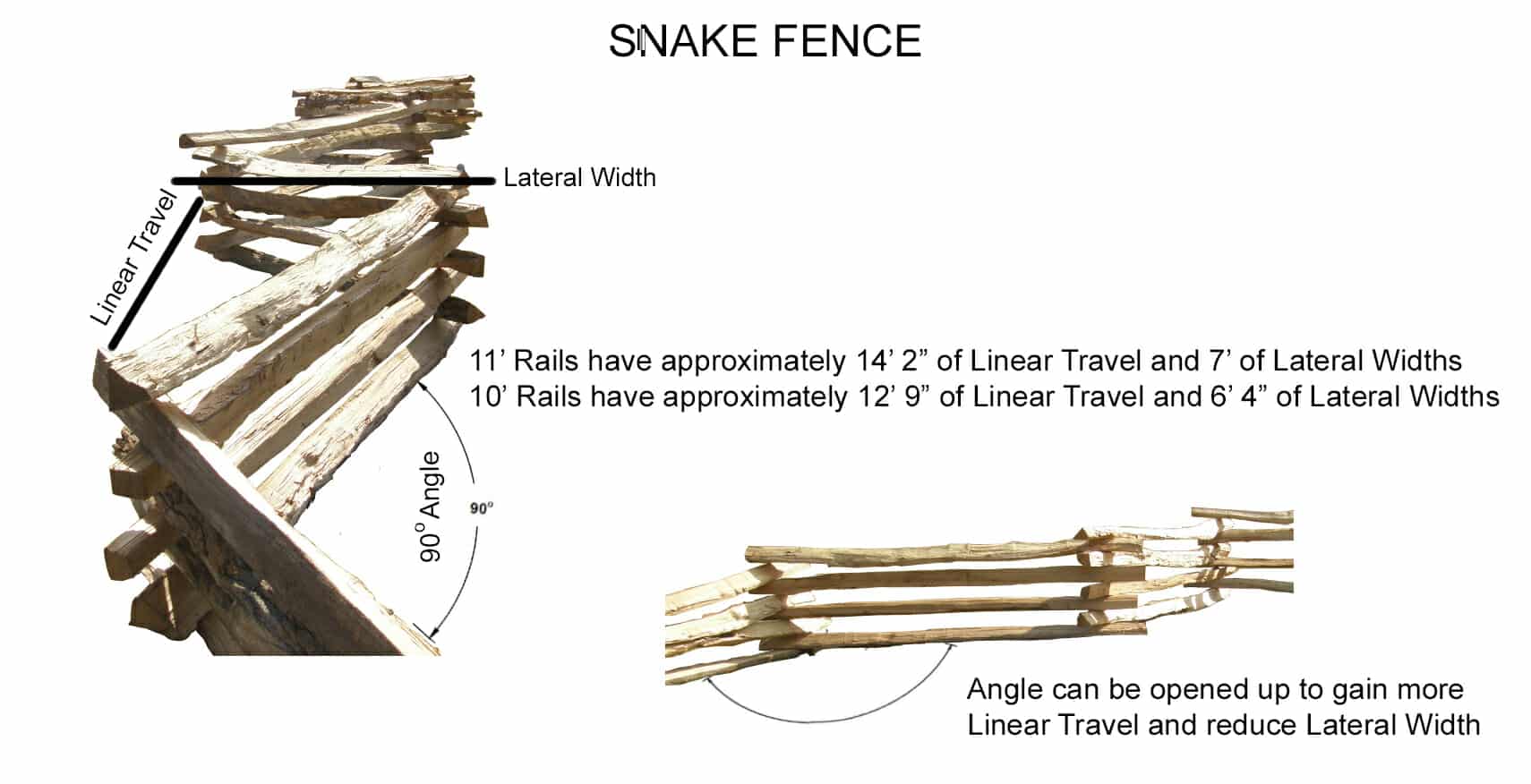

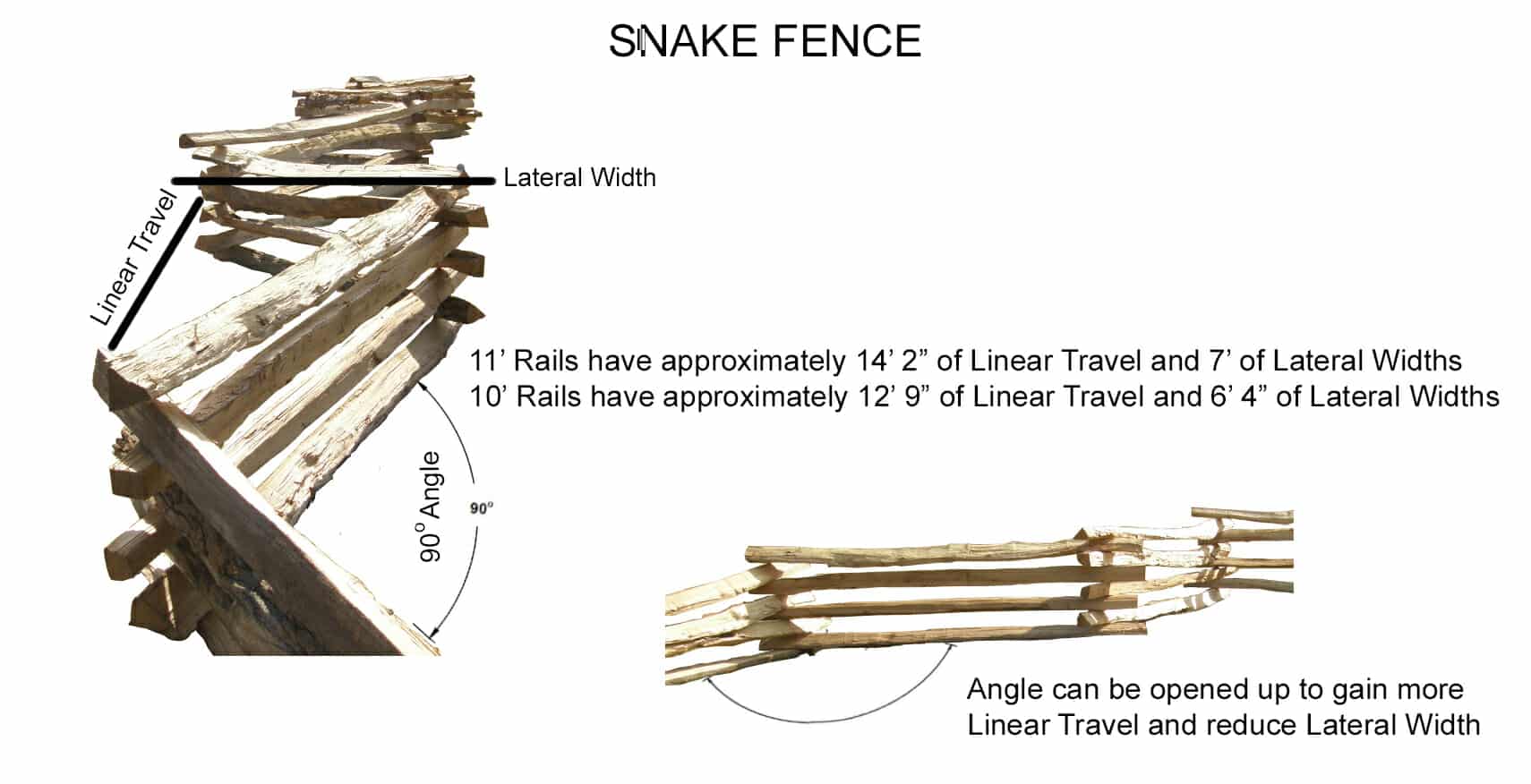

- For a “snake fence”: you can use the same principles as above, but the variance of the degree you place for your rail intersection, will be a function of the look you are seeking and how your land lays. These are variables we cannot account for. The maximum intersection of your rails is 90 degrees

Tools and Supplies Necessary to Install

If you are using posts you will require:

- a posthole digger or auger to drill the holes

- a shovel to fill the holes and a tamping bar to compost the soil

- a saw or ax may be helpful to trim the rails so they fit the space between the posts

- concrete – if you cannot bury a post due to rocks or other site issues that will not allow you to place the post deep enough, you may choose to use concrete to secure the posts in place.

If you are doing a two to a three-rail fence between 2-posts, you will also need:

- 12 gauge or smaller galvanized or stainless wire cut in 12 to 16″ lengths

- wire cutters

- hammer

- staples with a staple gun for larger projects.

If you are doing a snake-rail fence you will require:

- flat rocks for a traditional installation. You will place the first rail of each fencing section on the rock to avoid contact with the soil and increase your fence longevity.

Installation

For A Two-Post Fence

Plan to bury up to 2’ of the post for stability. The soil on your site can impact this. Your posts should be set into the ground and the soil then tamped back around them. If you cannot bury a post 2 feet due to rocks or other site issues that will not allow you to place the post deep enough, you may choose to use concrete to secure the posts in place. Space the posts approx. 6″ apart for both standard and government grade rails. The rails may have to be whittled on the ends to pass between the posts, but try to make them fit tightly as this strengthens the fence.

Hanging Rails Between Posts With Wire

We suggest you use 12 gauge or smaller galvanized or stainless steel wire cut in 12 to 16″ lengths. If you are using a lighter gauge wire, you may need to braid it for strength. Twist a loop on one end and fasten to one of the posts using a fencing staple. Pull the wire into position on the second post and twist another loop at a location on the post suitable for the second staple. Cut off any excess wire and repeat this at desired locations.

For A Snake-Rail Fence

Site-specific issues like rocks, soil conditions and lay of the land along with scarcity of nails and wire demanded that traditional builders of fences design alternative solutions. With wood and field stones in ample supply, the snake rail fence held the answer. If you require exacting methods, you may find this fence very frustrating as your angles may depend on the lay of your land, or your budget to maintain a traditional 90 degree intersection. But if you like being in contact with your land and adjusting to its ebb and flow, this fence is a great way to express a unique human-nature connection. For the traditional installation and to increase longevity of the rails, place a flat stone beneath each section of rail to elevate it off the ground. Crisscross your rails to create the degree of your choosing for the intersection, and allow a minimum overhang of 6” past center to stabilize each section. People have straightened the angle of intersection greatly to decrease the amount of rails required. They have added wire to hold rails in place. If you choose to do this, then plan for increased maintenance, stabilizing the fence over time as this is not a sturdy solution. For a sturdier fence, posts may be placed in an opposing vertical position leaning against the intersecting ends of the fence. See our photo gallery for examples.

Why black locust wood?

- Rot-resistant – Black Locust (Robinia Pseudoacacia) is the strongest and most rot-resistant wood indigenous to North America. It will remain beautiful and withstand years of outdoor exposure.

- No chemicals- Natural rot resistance means that no chemical pressure treatment is needed, and none will leach into surrounding soils. This makes the material a great choice for organic orchards.

- Long-lasting- Rails laying atop the ground have lasted for over 100 years. Posts set in the ground last about 20 years.

- Fast-growing and prolific – Black Locust is also a sound environmental choice. Black Locust is a very fast-growing hardwood tree.

Is the fencing functional as well as beautiful?

- Strong- Black Locust has a Crushing Strength of 10,200 lbf/in2 (70.3 MPa)

- Will hold large and medium animals with consideration to required heights and rail spacing. Make sure your installer has built with this material in the past and understands the dynamics of your location and the needs of your livestock. Small animals can be contained by adding the correct gauge wire.

- Gates can be added to achieve the look and functionality that you need.

Is the Bark House style historically accurate?

Prominent customers include federal and state parks requiring historically accurate rails. We have researched and compiled numerous construction methods employed throughout different times and regions and showcase those in our photo gallery.

How much do the rails weigh?

*please note that the listed weights are approximations, and actual weights may vary.

- 7′ Government = 45 pounds each

- 7’ Standard = 30 pounds each

- 10′ Government = 50 pounds each

- 10’ Standard = 40 pounds each

- 11′ Government = 52 pounds each

What kind of posts can I choose from?

We offer split posts. They are 7’ long and 3-4 inches greater in circumference than the rails. Standard Grade is 12” minimum circumference and Government Grade is 15” minimum circumference. We do not currently supply posts with holes or rails with tapered ends.

Why do you sell two grades of rails?

We have Standard Grade Rails with a minimum circumference of 8″ and Government Grade Rails with a minimum circumference of 12″. When we split, we aim for the larger Government Grade. The by-product of that is the smaller Standard Grade and it is measured to be no less than 8” in circumference along the span of the rail. We do not supply rails with tapered ends.

How are the black locust rails and posts bundled for shipping?

- There are 30 rails per bundle.

- There are 20 posts per bundle.

What’s required for installation?

Please see the Product Guides and Installation tab for detailed information.

How much fence will I need?

Please see the Product Guides and Installation tab for detailed information.

How much of the post should I bury in the ground for a 2-post fence?

Plan to bury up to 2’ for stability. The soil on your site can impact this answer.

Do I need concrete or gravel to set the posts in?

Your posts should be set into the ground and the soil then tamped back around them. If you cannot bury a post due to rocks or other site issues that will not allow you to place the post deep enough, you may choose to use concrete to secure the posts in place.

Should I char the ends of my posts to increase longevity?

The ancient Japanese method of increasing the lifespan of wood called Shou Sugi Ban is increasing in popularity in the US, and this question is starting to come up more. There are points on both sides of the argument for and against this practice. We can’t currently advise you on this method.

What lengths are available for rails?

Rails are available in 7’, 10’, and 11’ lengths.

How much “taper” should I expect along the entire length of my rails and posts?

Many clients have experience purchasing rails that taper too thin. At Bark House, we establish a minimum circumference for each grade of rails and posts and we craft the rails to that minimum. Standard Grade Rails have a minimum circumference of 8″ and Government Grade Rails with a minimum circumference of 12″. Bark House rails and posts do not taper.

If you have minimum standards, what do you do with all the waste you produce?

Black Locust is an excellent wood for heat. Many people in mountain regions still heat their homes this way. We donate all the by-products to support people on low fixed incomes in our community.

Where is the black locust wood sourced from?

We source black locust in the Appalachian Mountain chain, close to our manufacturing facility. This way we can directly observe the impacts of tree removal on forests and monitor growth to removal ratios.

Do you deliver?

We do deliver. A full truckload hauls 900 pieces. We charge a per loaded mile rate and can provide a quote to you. To receive an order, your site must be tractor-trailer accessible and you will need a forklift onsite for unloading.

What do I need to know about ordering timeframes?

Bark House® Black Locust Split Rails are more popular than ever. Larger orders generally require a minimum 3-month wait period. You can secure your place in production with a 50% down payment and 100% before shipping.

What are some options to secure the intersecting rails of a snake fence like the one at Yorktown?

With the Yorktown fence, the brace rails buttress the top rail from falling by pinning the joint between the two diagonals. The other type of corner bracing uses 2 poles or rails driven into the ground slightly. They form an x pattern over the joint and then a “rider rail” is dropped down in the x notch. This provides the weight to strengthen the joint as well as gaining some extra height.