Bark House® is the original design manufacturer of poplar bark shingles and the only company that has always manufactured 100% of bark shingles in-house to ensure quality at every step of the process. Our process begins with reclaiming a waste product of the forest industry. The structure of bark is complex and the attributes that make it last must be understood when grading this a-typical material on intake. Material selection, drying in kilns specifically designed for this material, and squaring are delivered by an expert team, trained properly in these important steps to ensure product longevity.

Bark House® is the only company that has always performed 100% of grading and manufacturing in-house. This translates into products that last.

Grading Standards Ensure Material Viability

Our natural wall finishes are crafted from tree bark that was a waste material of the forest industry. This is unlike other wood products that have standardized grading rules established by the National Hardwoods Lumber Association. The NHLA rules help determine the value and what products can be made from the wood. These standards also allow for consistent communication across industry sectors and to customers. There are no industry standards in bark grading and no degree programs exist. Without proper grading, the material integrity can be compromised and products made of bark will not last.

Over thirty years ago, company co-founder and product designer Marty McCurry saw the potential of the material in crafting wall finishes that connected people to the forest. He identified the structural qualities necessary for the bark to be up-cycled into a viable product. Proper grading of bark is a complex process based in science. With educational preparation in Pulp and Paper and Chemical Engineering from NC State University as well as Architecture at UNCC, McCurry established the standards used exclusively at Bark House in the making of beautiful and lasting bark wall finishes.

The proper grading and culling of the bark material is an important first step that determines the viability of the bark and leads to product longevity. The variables center around the cellular structure and growth pattern of the bark and show up on the surface when you know what to look for. Elevation, latitude, location of the tree in hollows or ridges, wet or dry locations, the sun’s exposure from one side of the trunk to the other, how close the bark is to the ground or the canopy, and invasions by pests all have specific impacts that affect the structure and performance of the bark in a building application. The experts at Bark House have been trained in identifying these structural patterns. They have learned the material that must be culled and the bark that makes the grade.

Stringent Manufacturing Ensures Product Longevity

Our dry kilns are the first to be designed especially for the drying of bark. They earned the NC Governor’s Award for Innovation. Our proprietary drying process is tightly controlled with moisture measured along several steps. Diagonals are pulled on the bark to ensure it is squared after drying is completed. These important steps ensure longevity and save costs on installation time and product replacement.

Client Support Ensures Correct Installation For Lasting Projects

Builders require guides and support for the correct installation of products. This is never truer than for this non-standard material. Proper installation is the final step in ensuring product longevity. Our guides were written by the product designer with thirty years of filed-tested success.

What is poplar bark shingle siding?

Bark House is the original design/manufacturer of Poplar Bark Siding. This exterior product is manufactured from the peeled bark of Tulip Poplar Trees (Liriodendron tulipifera). The bark, which is historically a waste product in lumber operations, is harvested to become siding before the logs reach the mill. The bark is graded, kiln dried, and squared with specific quality checks to ensure product longevity. Bark House® Poplar Bark Shingle Siding is a regenerative product.

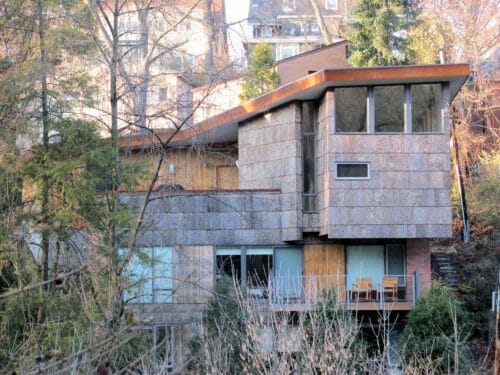

Are poplar bark shingles a rustic, modern or a high-design product?

Poplar bark is the perfect material for every design style. The muted tones juxtapose in commercial environments to add a natural element and a focal point, bringing a multitude of surfaces into context.

Is bark siding available now?

The harvest and manufacturing of bark siding is seasonal. Therefore, it is important that you contact our sales team and communicate your plan to use bark siding. It is possible that the product will sell out, in a given year. We will notify you if we begin to see inventory levels drop so you can meet your project timeline. Take a look at the bark harvesting process.

How long does it take to get poplar bark siding?

The production of bark shingles has a limited annual harvest season. We manage these limitations when clients inform us about their project plans. Once seasonal production begins, we rapidly process pre-orders. It is not, however, unusual that we will sell out of product at the end of the year, just before our harvest season begins anew. Share your timelines with us and we can advise you about securing product for your project.

How do I install Bark House® Poplar Bark Shingle Siding?

The best way to explain is to show you! Click to watch the Installation Video, or, if you prefer, click to read the Installation Guide.

If you have further questions, please reach out to Bark House for individual technical support.

Do I need a rain screen when I install poplar bark siding?

We don’t consider rain screens necessary because of the design of the installed shingles. The purpose of the screen is to ventilate between the substrate and the siding to mitigate moisture build-up that can occur with siding types nailed flat to the wall. Because the shingles and its felt backing are layered at an angle up the wall, there is already a space created between them and the substrate. Further, the shingles are convoluted on the face so this creates pockets of airflow at the lap line. A rain screen is actually an aspect of the natural design.

How do I figure coverage and waste factors for poplar bark shingle installation? What is the lap-factor required for bark shingles?

When installing any wall covering, you must account for waste factors. Here is our guide specifically for calculating how much poplar bark shingles that you will need: How many square feet of shingles do I need?

What maintenance is needed for exterior bark shingles?

Bark House poplar shingle siding is a maintenance free product.

Are Bark House® Poplar Shingles rated for fire resistance?

Poplar panels have been tested to be ASTM E-84-05 Class B Fire Rated, and a detailed report is available upon request.

Will my exterior bark siding change color over time?

Because it is a natural product, poplar bark shingles will develop natural aging qualities over time. Please see our page about the natural aging of bark.

Are bark shingles resistant to insects?

Poplar Bark shingles are very insect resistant. This link will explain how: White Paper: Insect Resistance

How are bark shingles shipped?

Bark House Poplar Shingles are shipped securely banded on pallets. It is important to keep the shingles under pressure while being stored. When stored without pressure, the bark may naturally attempt to warp. If you do not plan to immediately install the shingles, store the shingles in a protected environment and do not clip the tension bands.

What sizes are available for poplar bark shingles?

Our shingles are available in standard and premium thicknesses. Grades are a function of thickness. For exterior applications, only Standard and Premium grades should be considered. Shingles are available in 13”, 18”, and 26” heights. The widths of our shingles – all heights- will range from 6” to 48”.

What if I need a larger size bark shingle?

If your project requires larger sizes than our shingle offerings, consider using our poplar bark panels.

What is the difference between Standard and Premium Grade Shingles for exterior applications?

The only difference between Standard and Premium Grade Shingles is the thickness of the bark. Standard Grade will range from 9/16″-7/8″, while Premium Grade will range from 15/16″-1 1/2″. There is no significant difference in shingle performance, but the Premium Grade offers deeper ridges in the bark texture. It simply becomes a character and aesthetic preference.

Are there samples of the bark shingles and finishes?

Yes! We have 6″ x 6″ samples that you can easily order via our website page, Sample Kits. Bark House samples are not discards, cut-offs, or scrap. They are hand-crafted just like full-sized products. The RAW™ (Reclaimed Appalachian Wood Waste) material we procure is not a commodity and not readily available.

How much does a pallet of poplar bark shingles weigh?

Premium Grade weighs 2.25 lbs per sq ft

Standard Grade weighs 1.75 lbs per sq ft

Interior Grade weighs 1.5 lbs per sq ft

The packaging material is of nominal weight, but if you’re concerned, ask your customer specialist.

Does Bark House offer a trade discount or volume discount?

The majority of our clients are professionals, so that discount has already been accounted for in the price.

What are the economic benefits of purchasing from the original manufacturer of bark siding?

One of the greatest benefits for using Bark House Shingles is the cost savings from not having to paint or stain. Our shingles are comparably priced to other premium wood sidings that also have to be painted or stained. Given that this painted or stained wood needs to be re-coated every three to five years at a current range of $2 to $5 per square foot depending on the wood’s condition, just your maintenance costs alone can exceed the cost of our shingles in just 10 years.

Our bark grading process ensures that thicknesses are consistent and perfectly square. These measures allow for rapid on-site installation which save you time and money.

With Bark House Shingles, put them up and forget the maintenance for good! Read how beautifully our shingles age over time: The Natural Aging of Bark Shingles

Can I apply bark shingles to a block or cement surface?

Assuming the wall application is vertical and has proper overhangs, you would need to attach pressure-treated wood strips to the block or cement surface first. Then attach ½” plywood and follow our standard bark shingle installation guide.

How much will my bark shingle order cost to ship?

Bark Shingles are shipped in the most economical way possible for the size of your order. Most shipments will be done via Less Than Truckload (LTL) freight, and the cost will depend on your order size and shipping location. We are happy to provide you with a quote. Please email [email protected].

What is the minimum quantity of bark shingles that I can order?

Our minimum order is 48 square feet, regardless of Grade or Height.

What makes bark siding distinctive on my building site?

Once you install Bark House Poplar Shingles on your building, you can expect the bark to take on characteristics of your environment. The sun, wind, and rain will allow the bark to become uniquely yours. To learn more about the aging of poplar bark shingles, see this link: The Natural Aging of Bark House® Shingles

We work with architects and designers all over the globe to create unique product applications that have contributed to award winning designs. We welcome the opportunity to do so with you.

Can I customize bark shingles?

Product Options makes your fit and customization finish unique. As you scroll down on our Bark House® Bark Shingle page you will get to choose your thickness, height, and consider if you will stagger the shingles on your application. If you need this product laminated to a substrate for your specific application, we can do that too!

Chicago childcare center required shingles that were laminated to 1/4″ Hardie backer board.

Which shingle height should I order? Does shingle height matter?

Options in product height allows your creativity to shine. Unless you are working with an historical application where a specific shingle exposure is preferred, the choice of height is simply for aesthetics in design.

Can Bark House help me to share my unique project with others?

Projects with Bark House products have been featured in over 250 well-positioned media outlets. We want to celebrate the completion of your unique project. Share your project with us!